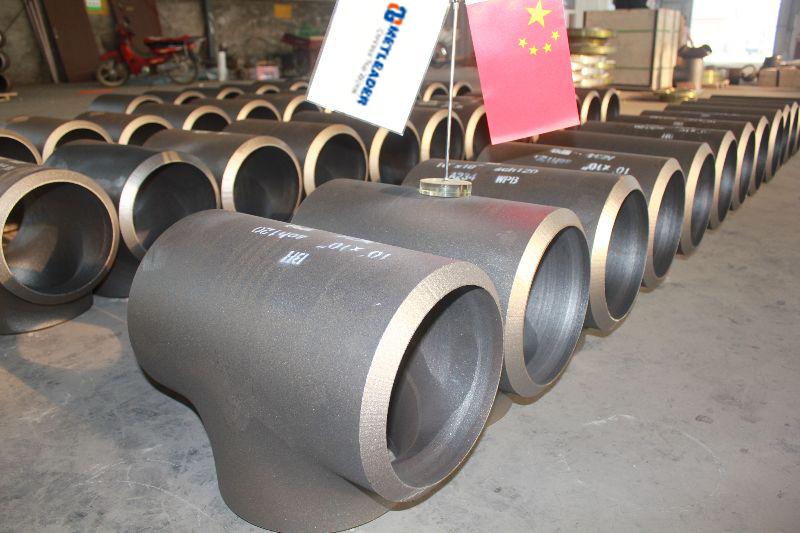

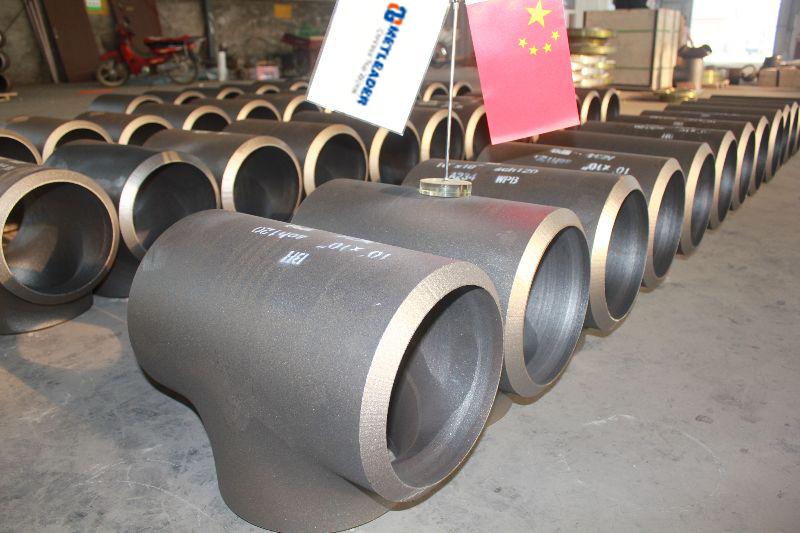

Carbon steel pipe tee fitting

Metleader is a fairly powerful enterprise. Professional production, through and strict implementation of quality management system so that products are standardized, serialized. Our company is the production of seamless tee, high pressure tee, schedule 80 steel pipe tee fitting, straight seam tee, hot pull tee, welded tee, equal diameter tee, with from forging, heat treatment, machining, physical and chemical inspection, surface treatment to packaging and shipping to implement the integrated production strength.

Schedule 80 steel pipe tee fitting refers to the wall thickness f steel pipe tee is sch80, that is 3 inches, which is usually used in the high pressure projects.

On the processing of the reduced tee requirements and precautions.

1.Reduced tee machining technology is very important, its in the extrusion process the pressure is too high or too low will cause the formation to be bad, causes the repair or the scrap, the reduced tee in the welding process electric current, the voltage, the speed and so on will affect the welding quality directly, the push speed of the hot-push tee should be adjusted to the heating speed of the heating to the specified temperature, otherwise it will cause the bad shape of the tee. Such as the schedule 80 steel pipe tee fitting, its a kind of widely used tee.

2.In the shape of the tee, it takes several deformation to reach the required shapes and sizes. The contour of the reducer tee is determined by the shape of the inner cavity of the forming die, therefore, the main factor of the quality of the tee is the shape of the mould core, including the inner and outer diameter of the tee, the roundness, and the roughness of the side directly related to the shape of the mould core, the quality of the mould core is decided by the three-dimensional forming. So the shape size of the control module is critical to the tee.

3.The contour of the three-dimensional tee is determined by the shape of the inner cavity of the forming die, so the dimensions of the three-link shoulder, the shape of the head and the transition parts of the branch tube reflect the reliability of the tee, which depends on the forming mode, so the design, manufacture and maintenance of the tee. When our customer bus schedule 80 steel pipe tee fitting, we surely produce the products strictly according to the standard.

Schedule 80 steel pipe tee fitting refers to the wall thickness f steel pipe tee is sch80, that is 3 inches, which is usually used in the high pressure projects.

On the processing of the reduced tee requirements and precautions.

1.Reduced tee machining technology is very important, its in the extrusion process the pressure is too high or too low will cause the formation to be bad, causes the repair or the scrap, the reduced tee in the welding process electric current, the voltage, the speed and so on will affect the welding quality directly, the push speed of the hot-push tee should be adjusted to the heating speed of the heating to the specified temperature, otherwise it will cause the bad shape of the tee. Such as the schedule 80 steel pipe tee fitting, its a kind of widely used tee.

2.In the shape of the tee, it takes several deformation to reach the required shapes and sizes. The contour of the reducer tee is determined by the shape of the inner cavity of the forming die, therefore, the main factor of the quality of the tee is the shape of the mould core, including the inner and outer diameter of the tee, the roundness, and the roughness of the side directly related to the shape of the mould core, the quality of the mould core is decided by the three-dimensional forming. So the shape size of the control module is critical to the tee.

3.The contour of the three-dimensional tee is determined by the shape of the inner cavity of the forming die, so the dimensions of the three-link shoulder, the shape of the head and the transition parts of the branch tube reflect the reliability of the tee, which depends on the forming mode, so the design, manufacture and maintenance of the tee. When our customer bus schedule 80 steel pipe tee fitting, we surely produce the products strictly according to the standard.

Previous:What are the different types of fittings?

Next:Packaging requirements and specifications for ASME pipe fittings

Next:Packaging requirements and specifications for ASME pipe fittings