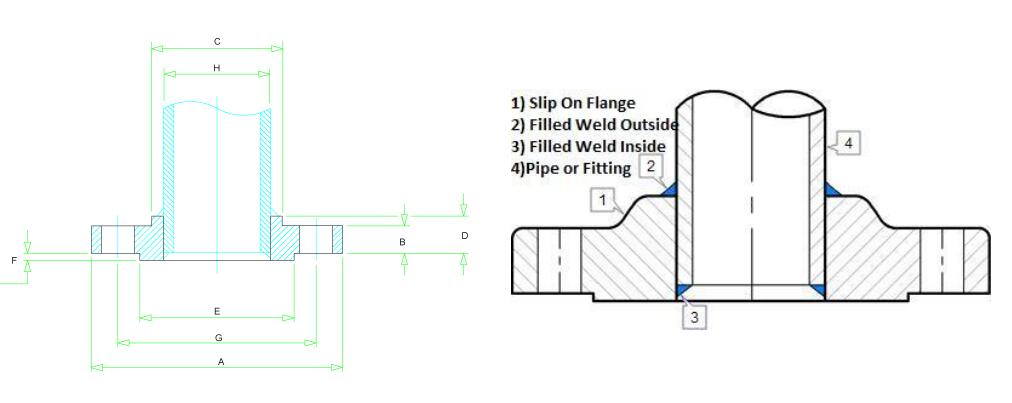

ANSI 150 slip on flange dimensions

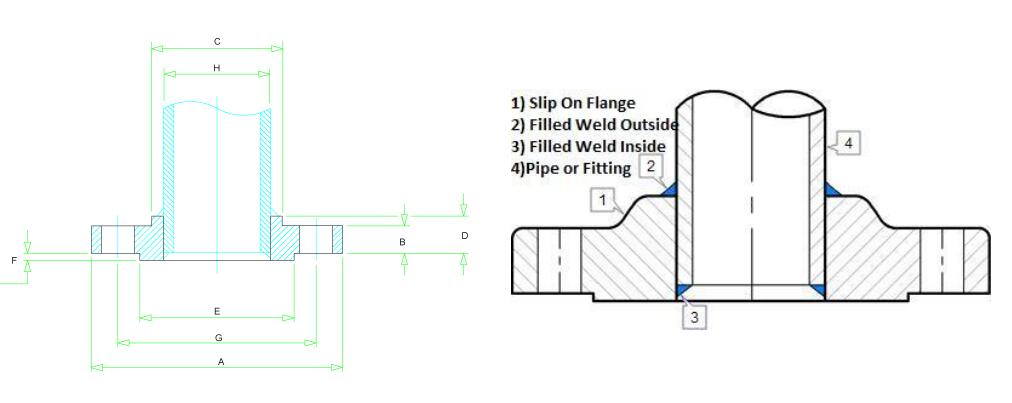

ANSI 150 slip on flange dimensions include outside & inside diameter of body, Bolt Circle & Bolt Hole Diameter, Length of the Hub, thickness of flange etc. These dimensions are very important when inspect them. Please see the below picture.

Beijing Metleader Pipeline Technology Inc. www.metleader.com with professionally and abundant manufacturing experience of ANSI slip on flange for more than 36 years. We offer high quality slip on flange, accurate size, high corrosion resistance. These flanges ANSI B 16.5 Class 150, high pressure flanges can be easily assembled into any pipe without welding. Slip on flange, ANSI B 16.5 150 class, 150 class ANSI B16.5 can be used for medium and low pressure pipeline service. We provide these slip on flanges ANSI B 16.5 150, suitable packing to avoid any damage during transportation.

We provide all kinds of ANSI B16.5 150 level slip on flanges in accordance with relevant industry standards. Our series of flanges are widely praised for their size accuracy and corrosion resistance and rust resistance. These flanges require less maintenance and are ideal for high temperature and high pressure applications.

The dimensions of ANSI 150 slip on flange that we can supply is from 1/2 inch to 60 inch according to standard ASME B16.5 and ASME B16.47.

The ANSI 150 slip on flange has a low neck height, which improves the rigidity and load-bearing capacity of the flange. Compared with weld neck flanges, the welding work is large, the welding rod consumption is high, and the high temperature and high pressure and repeated bending and temperature fluctuations cannot be maintained. However, the on-site installation is more convenient, and the procedure of shooting and rubbing the weld seam can be omitted.

One very important point of slip on flange that how to set the neck size of slip on flange (SO)? 1. The effective thickness of the small end of the flange neck is determined by the outer diameter of the selected pipes;

2. The effective thickness of the large end of the flange neck is determined using the assumptions first and then the method of checking the stress (axial stress of the flange neck, radial stress of the flange ring and tangential stress of the flange ring). Specific calculation please according to referenced computational formula.

Beijing Metleader Pipeline Technology Inc. as a professional producer of slip on flange always supply high quality slip on flanges and other types of flanges as per ANSI B16.5 150 class. We not only provide high quality and stable quality flange but also provide thorough after sale service. Choosing us is just choosing safety, special customised service is also available.

Beijing Metleader Pipeline Technology Inc. www.metleader.com with professionally and abundant manufacturing experience of ANSI slip on flange for more than 36 years. We offer high quality slip on flange, accurate size, high corrosion resistance. These flanges ANSI B 16.5 Class 150, high pressure flanges can be easily assembled into any pipe without welding. Slip on flange, ANSI B 16.5 150 class, 150 class ANSI B16.5 can be used for medium and low pressure pipeline service. We provide these slip on flanges ANSI B 16.5 150, suitable packing to avoid any damage during transportation.

We provide all kinds of ANSI B16.5 150 level slip on flanges in accordance with relevant industry standards. Our series of flanges are widely praised for their size accuracy and corrosion resistance and rust resistance. These flanges require less maintenance and are ideal for high temperature and high pressure applications.

The dimensions of ANSI 150 slip on flange that we can supply is from 1/2 inch to 60 inch according to standard ASME B16.5 and ASME B16.47.

The ANSI 150 slip on flange has a low neck height, which improves the rigidity and load-bearing capacity of the flange. Compared with weld neck flanges, the welding work is large, the welding rod consumption is high, and the high temperature and high pressure and repeated bending and temperature fluctuations cannot be maintained. However, the on-site installation is more convenient, and the procedure of shooting and rubbing the weld seam can be omitted.

One very important point of slip on flange that how to set the neck size of slip on flange (SO)? 1. The effective thickness of the small end of the flange neck is determined by the outer diameter of the selected pipes;

2. The effective thickness of the large end of the flange neck is determined using the assumptions first and then the method of checking the stress (axial stress of the flange neck, radial stress of the flange ring and tangential stress of the flange ring). Specific calculation please according to referenced computational formula.

Beijing Metleader Pipeline Technology Inc. as a professional producer of slip on flange always supply high quality slip on flanges and other types of flanges as per ANSI B16.5 150 class. We not only provide high quality and stable quality flange but also provide thorough after sale service. Choosing us is just choosing safety, special customised service is also available.