how to weld on flange fittings

How to weld on flange fittings,first of all, it is necessary to prepare welding tools and perform different requirements of welding according to the different welded steel pipes or pipe fittings. The main flange welding process is as follows:

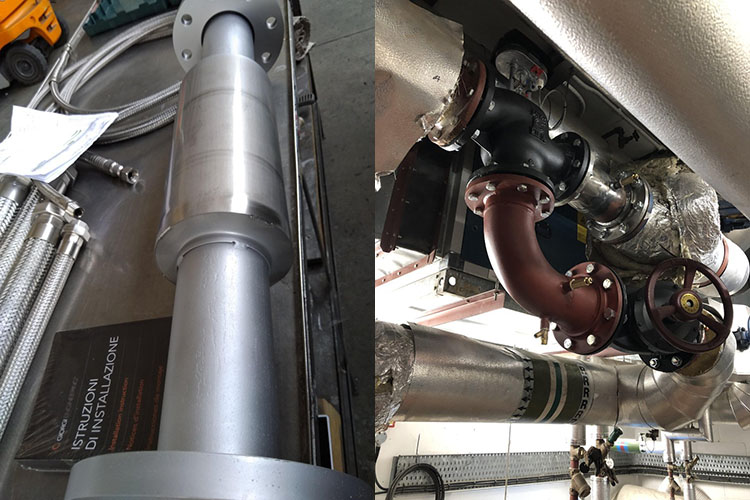

Flange welding process

Required equipment and tools A manual welding equipment, a handle angle grinder, an electric hammer, a flat surface.

Welding preparation: 1. Check the debugging equipment to ensure the normal operation of the equipment;

2. Prepare the Φ4.0J506 electrode for best drying at 300°C-350°C for one hour.

Welding process: 1. Assembly The vertebral body and the large flange are assembled according to the requirements of the drawings, and the large flange is divided into 8 equal parts.

2. Because of the thick flange and large groove, the welding adopts segmental symmetry and multi-layer welding.

Weld quality: 1. It is required that the strength of the weld be at least the strength of the mother village. The weld surface is smooth and smooth, with no defects such as burn-through, air hole, welding leakage, slag inclusion, undercut, and lack of welding. The remaining height is less than 2mm.

Precautions: 1. Be sure to use the J506 electrode for manual build-up and use low current welding. In strict accordance with the welding process welding.

2. Each time after welding a position, use a horizontal ruler to check the deformation of the flange plane.

3. One side of the welding hammer is used to hammer the weld to relieve the stress.